Why Aggregate Quality Matters for Concrete Strength

How Quality Aggregates Affect the Strength and Durability of Concrete

When planning a construction project, have you ever wondered why two concrete structures made with the same mix design can perform differently over time? Why does one remain strong and durable, while another cracks, deteriorates, or fails sooner than expected?

The answer often lies in one crucial component: the quality of aggregates.

Aggregates may seem simple—just stones, sand, or gravel—but they play a central role in determining concrete strength, workability, durability, and long-term performance. In fact, aggregates typically make up 60–75% of the total concrete volume, meaning the quality of these materials can make or break your concrete project.

This article explains why aggregate quality matters, how different characteristics affect concrete behaviour, and what engineers, contractors, and builders should look for when selecting aggregates for high-performance construction.

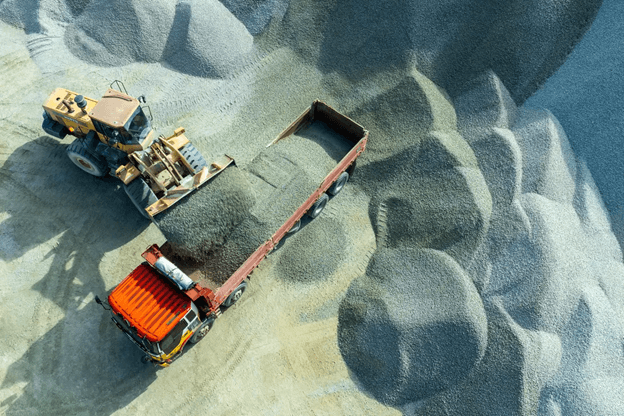

Why Aggregates Matter in Concrete

Concrete is a composite material made of cement, water, and aggregates (coarse and fine). While cement acts as the binder, it is the aggregates that give concrete its volume, structure, and mechanical performance.

Aggregates influence the following:

- Compressive strength

- Durability and resistance to weathering

- Shrinkage and cracking behaviour

- Workability and pumpability

- Bonding and load distribution

- Long-term structural integrity

High-quality aggregates help concrete achieve its intended strength and lifespan, while poor-quality aggregates can compromise the entire structure.

How Aggregate Shape Affects Concrete Strength

One of the most overlooked characteristics of aggregates is shape, yet it significantly impacts mechanical performance.

A. Angular Aggregates

- Provide better interlocking

- Increase mechanical bonding

- Improve compressive strength

- Often preferred for structural concrete

Angular particles “lock” together, making the concrete matrix stronger.

B. Rounded Aggregates

- Improve workability

- Require less water

- Common in river sand and natural gravel

However, rounded aggregates offer less interlocking and may slightly reduce overall strength.

C. Flaky or Elongated Aggregates

- Lead to weak zones

- Reduce strength

- Increase risk of cracking

Such aggregates are generally avoided in structural applications because they create weak planes within the concrete matrix.

Key takeaway:

Aggregate shape directly affects strength. Angular particles enhance load transfer, while flaky materials weaken the concrete structure.

Aggregate Size and Grading: Why It Matters

The size distribution (grading) of aggregates greatly influences concrete’s behaviour.

Well-Graded Aggregates

- Fill voids efficiently

- Require less cement paste

- Improve density

- Enhance durability

Well-graded mixes create a compact concrete matrix with fewer air pockets.

Poorly-Graded Aggregates

- Create voids

- Increase cement demand

- Compromise strength

- Reduce workability

Concrete made with poorly graded aggregates may shrink, crack, or deteriorate faster.

Aggregate Size

- Larger aggregates reduce shrinkage

- Smaller aggregates improve finish and workability

- Sizes must suit the structure (e.g., beams, slabs, columns)

The goal: achieve an optimal blend of coarse and fine aggregates for strength, density, and durability.

The Importance of Aggregate Cleanliness

Impurities such as clay, silt, dust, and organic material dramatically reduce concrete performance.

Contaminated aggregates may:

Prevent proper bonding between cement and aggregate

- Increase water demand

- Cause long-term durability issues

- Reduce compressive strength

Clean aggregates produce stronger and more consistent concrete.

Aggregate Strength and Hardness

Aggregates must be strong enough to withstand:

- Crushing forces

- Load distribution

- Environmental exposure

- Abrasion (especially in roads and industrial floors)

Weak aggregates reduce the overall load-bearing capacity of concrete, regardless of cement strength.

Why?

Concrete fails when aggregates fracture under stress. Strong aggregates resist crushing, enabling concrete to reach its designed compressive strength.

Moisture Content and Water Absorption

Aggregates naturally contain moisture, but excessive absorption affects mix accuracy.

High-absorption aggregates:

- Change water-to-cement ratio

- Reduce final strength

- Increase shrinkage

- Affect workability

Precise moisture measurement ensures accurate batching and consistent performance.

Durability: How Aggregates Affect Long-Term Concrete Performance

Concrete durability depends heavily on the aggregate’s resistance to weathering, chemical exposure, and physical wear.

Key durability factors include:

- Freeze–thaw resistance

- Abrasion resistance

- Chemical stability

- Resistance to alkali-aggregate reactions (AAR)

Poor-quality aggregates can lead to early cracking, scaling, or internal expansion that compromises the concrete structure.

How Aggregate Density Affects Concrete Behaviour

Dense aggregates produce:

- Higher strength concrete

- Better load distribution

- Lower permeability

Low-density aggregates (such as lightweight materials) are used for specific applications but are not suitable for heavy structural loads.

Choosing the Right Aggregates for Different Concrete Projects

Different construction applications require different aggregate qualities.

1. Structural Concrete

Requires:

- Strong, angular aggregates

- Low absorption

- High durability

Used in beams, slabs, columns, and foundations.

2. Pavements and Industrial Floors

Require:

- Hard, abrasion-resistant aggregates

- Good interlocking

- Stable granule shape

High traffic demands higher wear resistance.

3. Mass Concrete (Dams, Large Footings)

Requires:

- Larger, well-graded aggregates

- Low heat generation

- Minimal shrinkage

This helps reduce thermal cracking.

4. Decorative or Architectural Concrete

Requires:

- Specific colours or textures

- Highly graded fine aggregates

- Smooth finish capability

Aesthetic performance matters as much as strength.

The Cost of Using Poor-Quality Aggregates

Cutting corners on aggregate quality leads to expensive long-term problems:

Potential consequences include:

- Reduced compressive strength

- Cracking and shrinkage

- Reduced lifespan

- Scaling or surface deterioration

- Water infiltration

- Structural failure

Repairing or replacing concrete is significantly more costly than using quality aggregates from the start.

Key Qualities to Look for in High-Performance Aggregates

When selecting aggregates for concrete projects, consider the following attributes:

✔ Proper shape (angular, not flaky)

✔ Cleanliness (minimal fines or contaminants)

✔ Strength and hardness

✔ Suitable moisture and absorption levels

✔ Well-graded particle sizes

✔ Chemical stability

✔ Proven durability under environmental exposure

These characteristics ensure stronger, longer-lasting concrete that performs consistently throughout its lifecycle.

Testing Aggregates Before Use

Reliable concrete projects require aggregates tested through procedures such as:

- Crushing strength test

- Sieve analysis

- Specific gravity and absorption test

- Abrasion resistance test

- Soundness test

- Alkali-aggregate reaction (AAR) test

A construction materials supplier that conducts regular testing provides greater confidence in concrete performance.

Final Thoughts: Quality Aggregates Are the Foundation of Strong Concrete

Whether you're building high-rise structures, industrial floors, bridges, or commercial facilities, the strength and durability of your concrete depend heavily on one thing: the quality of your aggregates.

Choosing aggregates that are clean, strong, well-graded, and chemically stable ensures concrete that:

- Meets required compressive strength

- Withstands long-term environmental exposure

- Performs reliably under load

- Reduces maintenance and repair costs

- Supports safer, longer-lasting structures

In every concrete project—large or small—aggregates form the backbone of structural performance. Investing in high-quality materials today protects your project’s strength, safety, and value for decades to come.

Heidelberg Materials Malaysia - Aggregates Building Material

Ensure your concrete projects start with the right foundation. Discover reliable, well-graded aggregates designed for strength, consistency, and long-term durability: