Ready Mix Concrete Grades

Discover how to choose the right ready-mix concrete grades for durable, safe, and efficient construction projects in Malaysia.

Understanding Ready-Mix Concrete Grades: What You Need for Every Project

In the construction of high-performance structures—be it commercial buildings, industrial complexes, infrastructure, or high-rise developments—selecting the right ready-mix concrete grade is a decision that directly impacts structural integrity, safety, and project lifespan. For industry professionals and developers leading large-scale projects, this decision isn’t just technical—it’s strategic.

At Heidelberg Materials Malaysia, we’re committed to supplying premium-grade ready-mix concrete tailored for complex engineering demands. This article offers a detailed guide to understanding concrete grades, their uses, and how to make the right choice based on the performance criteria your project demands.

What Is Ready-Mix Concrete and Why It Matters in Large-Scale Projects

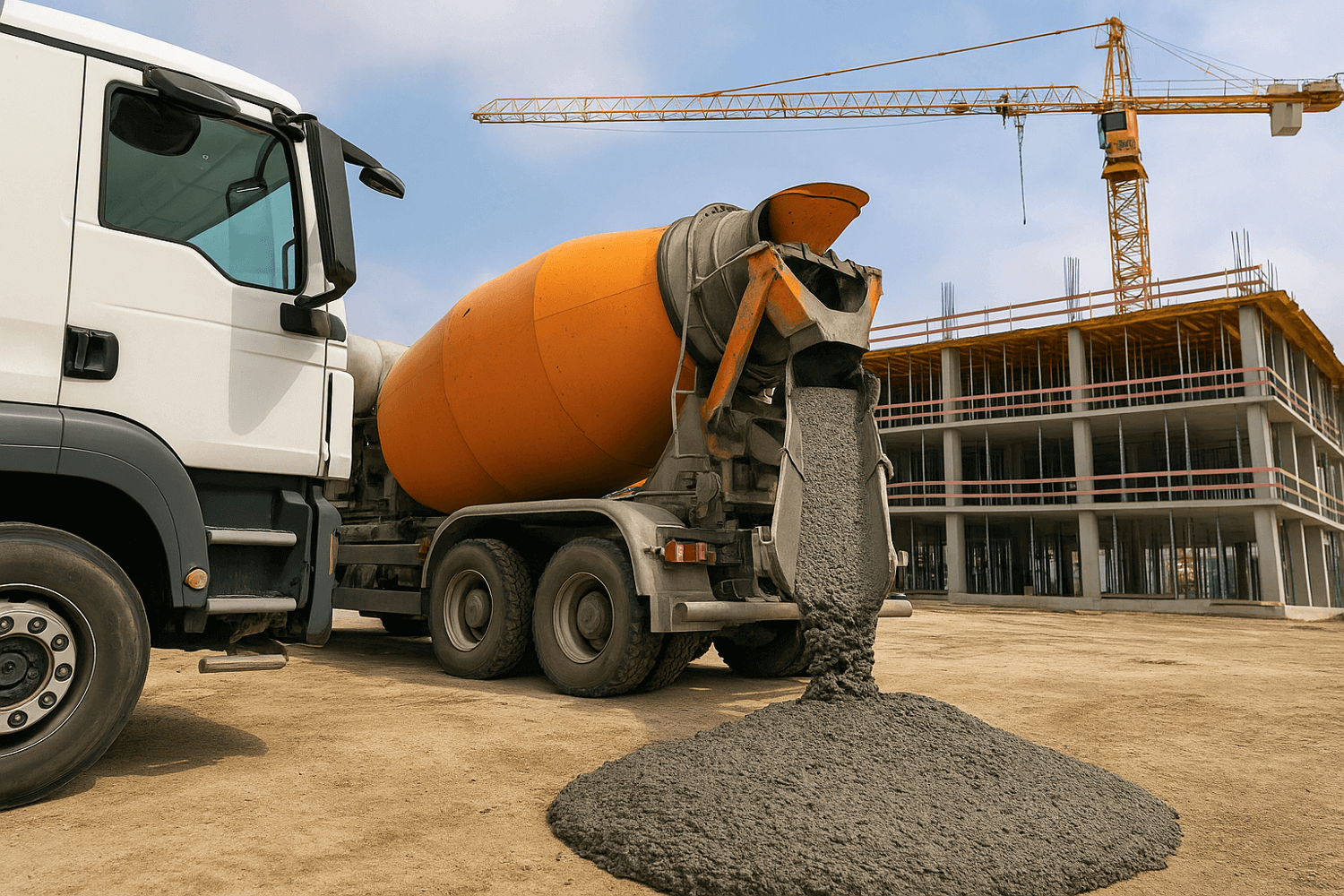

Ready-mix concrete (RMC) is a pre-engineered mix produced under controlled conditions in batching plants and delivered directly to construction sites. Unlike on-site mixed concrete, RMC ensures consistency, precision, and efficiency—critical for large projects where structural reliability and logistics coordination are essential.

It consists of:

High-performance cement

- Precisely graded aggregates

- Quality-controlled water content

Optional admixtures (for setting time, strength gain, workability, etc.)

For large-scale projects, using RMC reduces human error, minimizes wastage, and accelerates timelines—ensuring that stakeholders meet safety standards, structural codes, and sustainability benchmarks.

Understanding Concrete Grades and Their Structural Role

Concrete grades are classified based on their compressive strength measured in megapascals (MPa) after 28 days of curing. For large developments and infrastructure, this classification determines how the concrete will perform under heavy loads, in variable environments, and across decades of use.

Grades are denoted as C followed by two values (e.g., C30/37), indicating:

Characteristic strength (e.g., 30 MPa)

Cube strength used for design checks (e.g., 37 MPa)

These grades align with BS EN 206 and Eurocode 2 standards widely adopted across Malaysia’s engineering and construction sectors.

What Does "C" in Concrete Grades Stand For?

The "C" in designations such as C30/37 stands for Concrete, and it’s part of a classification system defined in the European Standard EN 206, which is also adopted in Malaysia and many countries with Eurocode-compliant construction practices.

Part | Meaning |

C | Concrete (EN 206 designation) |

First Number | Cylinder compressive strength in MPa |

Second Number | Cube compressive strength in MPa |

Concrete Grades Table for Major Applications

Grade | MPa | Application in Large Projects |

| C20/25 | 25 MPa | Lightweight load-bearing walls, non-critical slabs |

| C25/30 | 30 MPa | Residential towers, office buildings, parking decks |

| C30/37 | 37 MPa | Slabs, beams, and columns in multi-level commercial buildings |

| C35/45 | 45 MPa | Post-tensioned floors, precast segments, medium-span bridges |

| C40/50 | 50 MPa | High-rise structural cores, airport runways, load-bearing elements in malls |

| C50/60+ | 60+ MPa | Skyscrapers, elevated highways, precast tunnel segments |

Higher grades (C50/60 and above) are ideal for high-strength structural designs, seismic zones, and performance-based specifications.

Choosing the Right Concrete Grade for Your Project Scope

1. Structural Load and Stress

Heavy structures demand higher concrete strength. For example, in towers exceeding 30 stories, grades like C40/50 and C50/60 are typically used for the core, columns, and shear walls to withstand lateral and vertical forces.

2. Durability and Environmental Exposure

In large developments such as infrastructure or marine facilities, concrete must resist corrosion, sulphate attack, and freeze-thaw cycles. Heidelberg Materials provides durable, admixture-enhanced mixes to extend life cycles in harsh Malaysian conditions.

3. Speed of Construction

In high-volume pours, turnaround time matters. Our customized mix designs with controlled setting times and pumpability help contractors maintain aggressive construction schedules without compromising quality.

4. Compliance with Engineering Standards

Our ready-mix concrete complies with MS EN 206-1:2014 and local building regulations. We also support sustainability frameworks like GreenRE and LEED through low-carbon, eco-efficient mixes.

Advantages of Ready-Mix Concrete in Large-Scale Projects

✅ Precision and Consistency

Heidelberg batching plants use automated systems to ensure uniform mix proportions batch after batch, reducing human error across thousands of cubic meters.

✅ Time and Labor Optimization

RMC shortens the project timeline by eliminating on-site mixing delays. It allows efficient resource allocation, reduces site congestion, and speeds up vertical progress in high-rise projects.

✅ Advanced Mix Design Capabilities

We offer:

High-early strength concrete

- Self-compacting concrete (SCC)

- Pumpable concrete for tall structures

Fibre-reinforced and shrinkage-compensating mixes

✅ Sustainability & Environmental Control

Our RMC solutions can help meet green certification targets through:

Reduced cement content via SCMs

- Carbon footprint reporting

Optimized delivery logistics and recyclable packaging

Partnering with a Leading Ready-Mix Concrete Supplier in Malaysia

Choosing the right concrete grade is only half the equation—selecting the right supply partner is what guarantees project success. At Heidelberg Materials Malaysia, we bring more than just product—we bring end-to-end technical, logistical, and engineering support to ensure your project's structural performance and delivery timeline are fully aligned.

What We Offer:

Strategically located batching plants across Malaysia

- Fleet of modern transit mixers and pumps for high-rise access

- Dedicated quality control labs and on-site sampling

- Custom design services from foundation to superstructure

On-time delivery scheduling for critical path milestones

Whether you’re building bridges, towers, factories, or tunnels, we’re here to provide the backbone of your structure—literally and reliably.

Conclusion: Build It Strong, Build It Smart

Understanding ready-mix concrete grades is foundational for structural safety, cost optimization, and long-term performance. For developers and project owners in Malaysia, partnering with a trusted and experienced supplier like Heidelberg Materials means securing a solution—not just a material.

Every project is different. Let’s talk about the right mix for yours.

✅ Need high-performance concrete for your next large-scale development?

Explore our full range of ready-mix concrete solutions at Heidelberg Materials Malaysia, or contact our sales team for technical guidance and custom quotes.

- What are the common ready-mix concrete grades used in Malaysia?

-

The most common ready-mix concrete grades in Malaysia include Grade 25, Grade 30, Grade 35, and Grade 40, each offering different compressive strengths. The choice of grade depends on the structural requirement and type of construction project.

- How is concrete grade determined?

-

Concrete grade is determined by its compressive strength, measured in megapascals (MPa). For example, Grade 30 concrete can withstand a compressive strength of 30 MPa after 28 days of curing. The higher the grade, the stronger and more durable the concrete.

- Which concrete grade is suitable for residential construction?

-

For residential projects such as house slabs, driveways, and walls, Grade 25 or Grade 30 is typically recommended. These grades provide a strong balance of durability, workability, and cost efficiency for standard home construction needs.